High Precision Electrode Cutter

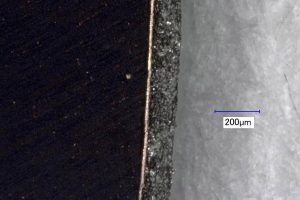

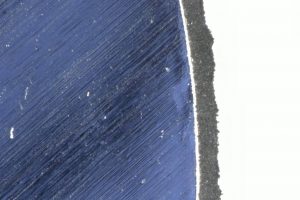

Accuracy and reproducibility of electrochemical tests do not solely depend on the choice of materials but also on simple geometric and mechanical parameters. The proper cutting of the electrodes is an often neglected factor. Torn and chipped electrode edges – although invisible to the bare eye – inevitably cause current inhomogeneity and are thus likely to affect experimental results. Especially life cycle and impedance results are prone to such artefacts. Electrodes being cut by conventional punching (stamping) with only one punch force show chipped edges and are not plain.

The EL–Cut is a high–precision punching tool specially designed for punching electrodes from coated Cu and Al foils. In contrast to conventional punching, electrodes being cut (fine blanked) by the EL–Cut are produced by three active forces and in tools with a few microns cutting clearance. The fine blanking process results in electrodes having clean cutting surfaces without torn or chipped edges and being almost perfectly flat.

The punching tool of the EL-Cut is permanently installed and cannot be changed. The EL–Cut is available in different versions, each with a different cutting tool. The diameter of a tool can be between 6 and 40 mm. Different shapes, e.g. squared, are possible.